About Us

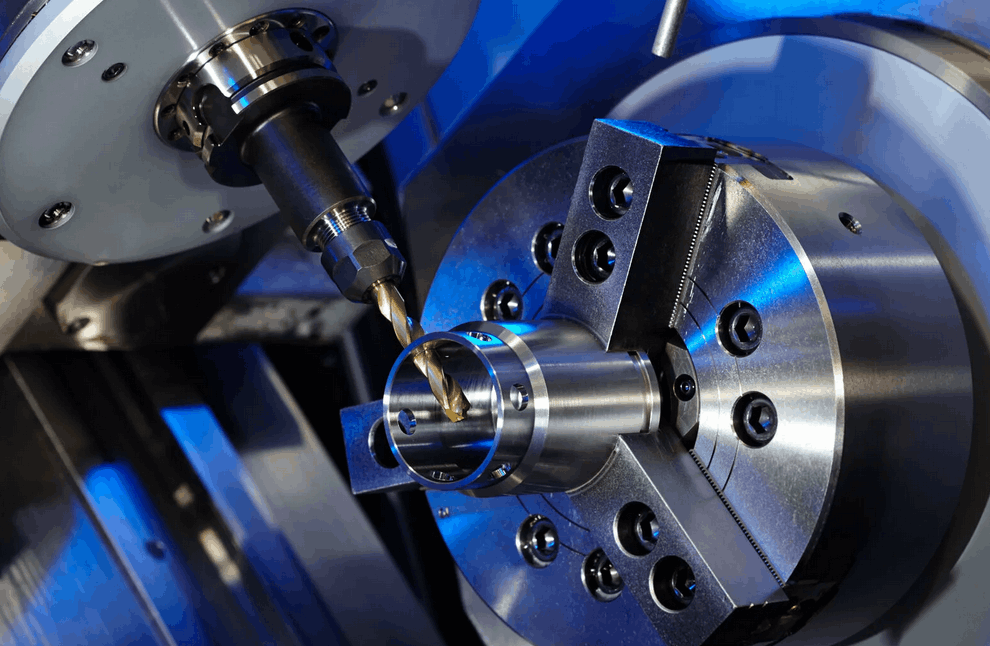

Disco Drive King's Lynn Ltd has been a trusted name in mechanical component manufacturing since its establishment. Our team consists of skilled engineers and technicians dedicated to delivering precision-crafted parts. We take pride in our ability to meet complex industrial requirements with innovative solutions.

Our mission is to support industrial operations by providing durable, high-performance components. We continuously invest in technology and training to enhance our capabilities. Client partnerships drive our growth, and we remain committed to excellence in every project.